Moveable Prefab Expandable Container House – 2–3 Bedroom with Bathroom – Overview

This moveable prefab expandable container house delivers rapid deployment, reliable durability, and comfortable living. Built on a galvanized steel frame with insulated sandwich panels, it is available in 20ft or 40ft options and is assembled in a controlled facility to avoid weather delays—keeping delivery costs low. Configurations support two or three bedrooms while maintaining compact transport size.

Products Description

Thanks to an efficient layout, a 2-bedroom or 3-bedroom home can fit into a single container for transport and then expand on site. The interior includes a kitchen with cabinetry, stone benchtops, cupboards, and sink (ships partly assembled), a bathroom with shower, toilet, and vanity with mirror, and two bedrooms (one large, one small) with interior doors and at least one window each. Pre‑wired outlets and switches serve the bedrooms, bathroom, kitchen, and living area, with dedicated power for kitchen appliances, electric water heating, and air conditioning.

Designed for guest houses, vacation homes, temporary living, work camps, and remote areas, the unit is 100% mobile and easy to transport. The galvanized steel structure with sandwich panel walls, doors, and windows is engineered to withstand harsh weather conditions while providing a comfortable, fully equipped tiny home.

What’s Included

- Lower kitchen cabinets finished (placement required)

- Kitchen sink and faucet installed

- Choice of countertop finish (from available supply)

- Full bathroom with shower and vanity

- Fully installed toilet

- Fully insulated with pre‑installed water connections

- Pre‑installed electrical and lighting throughout the home

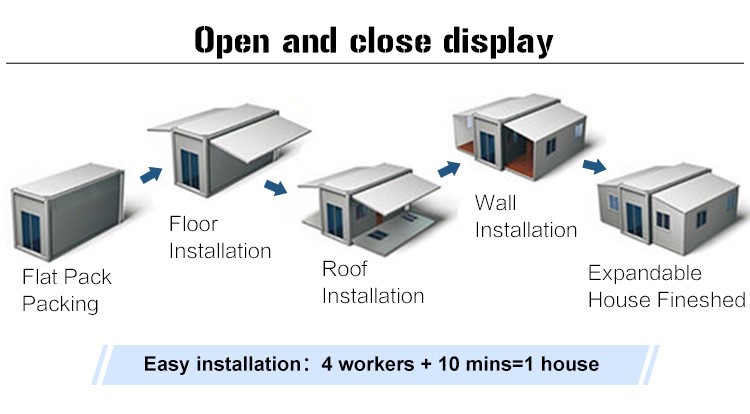

- Expandable walls for setup in under 10 minutes

- Compact, expandable unit for flexible delivery and placement

- 2–3 bedroom layouts available

Features & Advantages

- Water‑leakage prevention: Robust detailing for weather resistance.

- Affordable & practical: Options tailored to budget and local climate conditions.

- Flexible combination: Standalone use or horizontal combination to create larger open spaces.

- Fast assembly: On average, 4 workers can erect one container in about 10 minutes; major work completed in factory.

- Safe & stable: Light steel framing with spliced wall panels; thermal and sound insulation; seismic resistance to 8 degree; wind resistance to 11 degree.

- Cost‑efficient: First‑class materials, reasonable pricing, low base requirements, short completion time.

- Easy transporting: 2 units can be packed into one 40′ HQ shipping container.

- Repeatable use: Typical service life 20–30 years; can be disassembled and re‑erected at a new site.

Technical Specifications

| Specification | Details |

|---|---|

| Total Area | 37 m² (5.9 m L × 6.3 m W × 2.48 m H) |

| Functional Areas | Living & Kitchen 17.4 m²; Bathroom 3.3 m²; Bedroom One 7.8 m²; Bedroom Two 5 m² |

| Approx. Weight | 2.5 tonnes |

| Walls/Ceiling | 75 mm EPS galvanized steel sandwich panels |

| Frame | Heavy‑duty galvanized steel frame |

| Doors & Windows | Robust doors with aluminum frames; double‑glazed tempered glass windows |

| Electrical System | Wiring to moisture‑proof specs; components meet CE certification. Typical fittings: 2 LED lights, 2 ceiling lights, bedroom/living sockets, dedicated AC socket, 20A leakage protector. |

| Flooring & Trim | Standard grey PVC flooring; ceiling and floor skirting; corner trim and capping |

| Subfloor | 18 mm fibre‑cement board base, pre‑fitted to steel frame |

Product Pictures

Logistics & Installation (Key Info)

- Formats: 20ft and 40ft transport options to minimize delivery costs.

- Build flow: Factory assembly reduces weather/manufacturing delays for faster shipping.

- On‑site setup: Expandable walls enable rapid commissioning (setup under 10 minutes).

- Mobility: 100% mobile and easy to relocate for remote or temporary sites.